History of Pallet Stretch Wrap

You may not think so, but stretch wrap has a long history in industrial packaging. Indeed, it has become one of the fastest-growing industrial supply industries on the international market. Global demand for stretch wraps has been expected to increase steadily by at least 5.5% each year. It comes as no surprise, then, that stretch wrap has undergone a number of changes since its introduction to the chemical industry. The development of cast stretch wrap, known for its clarity, puncture resistance, and low noise when unwound, has played a significant role in the evolution of stretch wrap.

Early Days of Stretch Wrap

The LLDPE stretch wrap as we know it today was not always in the form we manufacture today. Like many other plastics, initial research that began its development was mostly created by pure accident. Polyethene itself is reported to have first been developed by Hans von Pechmann in Germany in 1898, decades before its real development began to take place fronted by the work of other chemists. It was a formation of the resin polymethylene – as it was named then – from the heating up of another chemical, diazomethane. The CH2 chains developed by this process would ignite further research and development around the world.

In the early days, clear pallet stretch wrap was used as a protective barrier for pallet loads, similar to cling film or rubber, to safeguard items from moisture, dirt, and debris during storage and shipping.

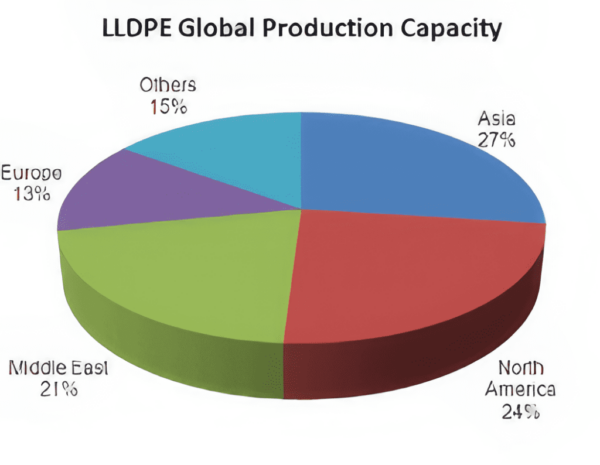

Industrial production for linear, low-density polyethene can be traced back to 1939 when Michael Perrin developed a process by which polyethene could be reproduced in a stable environment. Catalysts were created over the next few decades to further improve the polymerisation process, resulting in various temperatures and pressures by which polyethene could be produced. This included that of Karl Ziegler in 1953 and chemists at Phillips Petroleum, J. Paul Hogan and Robert Banks.

Both the Phillips and Ziegler catalysts were used to create high-density polyethene, which further developed its linear and low-density polyethene forms.

Industrial Development

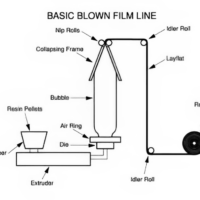

With the plastic resins created by these processes, it became more apparent that industries could begin to use them for much more than solid plastic items. In fact, the linear nature of these polymers is exactly what led to the development of their thin film formation. Despite their thin appearance, the linear carbon polymers could hold together firmly, providing a plastic with excellent tensile strength. Packaging solutions were about to become much more appealing to thousands of industries.

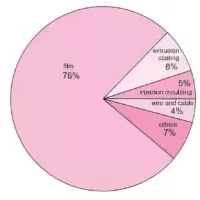

The first patent for a stretch wrap machine was filed in the United States in 1967 by R. W. Burhop. This was perhaps the first real sign of stretch wrap from polyethene being used in an industrial setting and possibly spurred the rest of the industry to take notice and begin the process of pallet wrapping using the stretch wrap. Two forms of polyethene were in circulation then: LDPE and LLDPE. Hand pallet wrap is particularly suitable for small to medium operations, with options like flush core, extended core, and coreless film available.

LDPE has been noted as the polymer with the lowest tensile strength and higher ductility, which means it has become more often used for industries looking for strong containers and those requiring film wrap or plastic poly bags. On the other hand, LLDPE is used for far more applications. Industries use it not only for packaging film coverings but also for other solid items, including containers and even toys. Machine pallet wrap offers benefits in securing and protecting items during storage and transit, with features like recyclability and puncture resistance.

Different types of pallet wrap films, including hand film and machine film, are available to suit various operations and customer needs.

Layering Up the Stretch Film

When stretch wrap was first developed, it was created as a mono film with only one layer. By 1972, stretch film had become a staple of the pallet wrapping industry. This was the case up to the 1980s. The machine stretch pallet wrap of 23 microns was a single layer that had a stretch capacity of only around 10-15%. (Mechanical brake machines). As you can imagine, this lack of flexibility, alongside the development of larger pallets and containers, needed to be addressed. That is where the idea of changing from mono film to multi-layered film came from.

Pre-stretch pallet wrap is a film that has already been stretched during the production process. This requires less force when wrapping a pallet and reduces the amount of film needed.

Initially, all stretch film was made from either LDPE or PVC. Industrial professionals first assumed that the P.V.C. was the best choice due to its 50% stretch ability, compared to 30% LDPE, but it soon became apparent that P.V.C. was more prone to tears and breakage than its LDPE counterpart. As such, LDPE became the focus of the global stretch film revolution. This meant that LDPE mono film was in industrial production throughout the 1970s, and changes only came in the 1980s when demands by companies for affordability and resilience of their films had to be met, introducing the newly developed LLDPE – a film far more capable of the stretch and resilience companies were looking for.

Many industries in the United States in 1982 began to create films that were three layers thick. Each layer had a different property in the film, including the middle piece for flexibility, one outer layer for clinging, and one for a smooth outside finish to the film. The stretchability grew to 100% for the most cost-effective product. However, it was not long before more layers were added to the LLDPE process. (The reasoning for power stretch machines).

Demand for stretch wrap only increased as usage expanded globally. Demand doubled between 1985 and 1990 to 500 million lbs a year, doubling yet again in the following five years, meaning that both pricing and durability needed to be addressed for businesses to make a profit on both the supplier and consumer sides of the packaging industry, from one to three layers to the 1990s introducing 5-layered films. Today, films can stretch up to 400% at 23 microns, meaning that a single one-meter roll of film can stretch up to 5 metres without tearing. For the packaging and wrapping industries, this was the cost-effective product they were looking for.

Today’s Stretch Films

In the last decade, we have made great strides with our stretch films. Extrusion technology has become so advanced that we have seen thinner 17-micron films with seven layers able to stretch up to 250%+ of their starting length. Now, as recently as 36 months ago, we are seeing the development of films with 55 layers at 10 microns that can stretch up to 300%+. Clear pallet wrap is now widely used for stabilising loads and protecting goods from elements and damage during transportation.

Fifty-Five layered BETA NANO films are stronger (have better load retention properties) than, say, 12 to 20-linear layered films with metallasoline and similar chemicals added to give them that extra stretchability. When any 10-micron film is stretched to 300%, it is only 3 microns thick. Therefore (per square meter), the 55-layered film has a latticed work effect for its strength, while the lessor layered films only have a linear (one direction) additive for stretchability and strength. Stretch film wrap is essential for securing and protecting items on pallets during storage and shipping, ensuring stability and safety.

Q.E.D. BETA NANO 55 layered have better load retention and puncture-proof properties. However, a word of caution: do not expect you’re nearly new (2/3 years old, or certain types of new pallet wrappers, generally the bargain-priced ones) with a 300% power stretch to maximise the advantages of any of the 12-micron films. In short, they do not possess the stretching and application technology to successfully apply a 3-micron film to the load. However, as every load is different, there are always exceptions to the rule. Talk to us; it’s free!

An example of how BETA NANO Wrap reduced the client’s film consumption by 60% and pallet wrapping costs by 40%

Four Alpha 508 pallet wrappers processed 1000 rolls of 12 microns at 300% (i.e., one meter became four) and produced 11 million 800.000 meters of stretched film wrapping 238.000 pallets over 12 months without complaint from either the film or the Alpha pallet wrappers. The average cost of wrapping a pallet was only 18p. Payback on these machines was only seven months.

Hand stretch film is also designed to be applied manually with innovative hand pallet wrap dispensers. Different core types, such as flush core, extended core, and coreless film, are available, each suitable for different applications.

Q.E.D. A 12-micron, 55-layered film will stretch 300% and still offer high load retention properties. The 23-micron film will stretch to 400% and more. The Alpha 508 can successfully apply all of these types of film to the load every time. It’s just that it possesses state-of-the-art Technology.

Focus Packaging 01902 570 292. Email sales@focuspackaging.co.uk. www.palletwrapperuk.co.uk

Summary

The extrusion process is starting to become more useful for the packaging industry in its development of stretch film, and it has been the tireless efforts of just three businesses to create these films. Their commitment to very substantial amounts of capital expenditure to purchase state-of-the-art extruders and to commit to individual Research and Development projects in the user market is what has really started the process of creating thinner, more durable films for the market.

Focus Packaging can offer a range of machines and stretch films from 7 microns to 33 microns. Suitable for all types of pallet wrappers, mechanical brake power stretch pallet wrappers working with 150% to 300% stretch and now up to 400% plus stretch. Different machines for wrapping pallets can significantly reduce plastic and film usage, benefiting various volume users and load sizes.

The objective is to offer you the cheapest and best-wrapped pallets possible for your application.